With the rapid development of industry and science and technology, Jinlai Technology has been put into automated production many years ago, in the coming 2019, our company will increase investment in automated production and increase a number of automated

production lines. Next, the small edition of Jinlai Technology will take you into the automated production workshop of Jinlai Technology to see the style of automated production.

With the rapid development of industry and science and technology, Jinlai Technology has been put into automated production many years ago, and has come 2019 Next year, we will increase investment in automated production and increase a number of automated

production lines.

Next, byJinlai Technology We can take you into the automatic production line of Jinlai Technology, a glance at the style of automated

production:

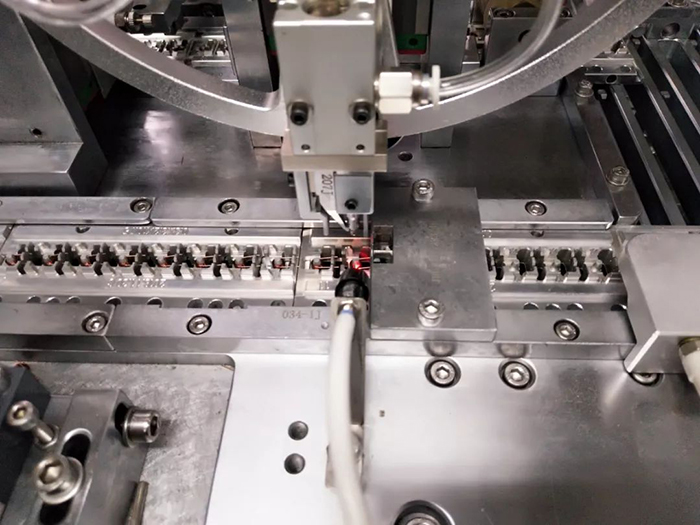

Integrated forming inductance automatic winding production lines

Integrated forming inductance automatic packet measuring workshop

Integrated forming inductor automatic production line

Spot welding Angle forming and baking

The purpose of automated production is to reduce costs. Why can we reduce costs by using automated production models? The direct impact of automated production is labor costs:

Automated production line is to upgrade the original ordinary production equipment, redesign the entire production line according to the production process to achieve the purpose of automated production and reduce manual input.

Put into automated production, manual operation processes can be replaced with machines, just add one or two small automation equipment or an automated production line, so that it can be used 2 Individual worker substitution10-100 The workload of people

greatly reduces the labor.

The use of automated production can overcome slow manual operation, unstable accuracy, material waste, low work efficiency, serious tool wear and other defects, can make greater use of raw materials, improve production efficiency, achieve manual off-machine

operation, ensure production safety, and form a large-scale management workshop.

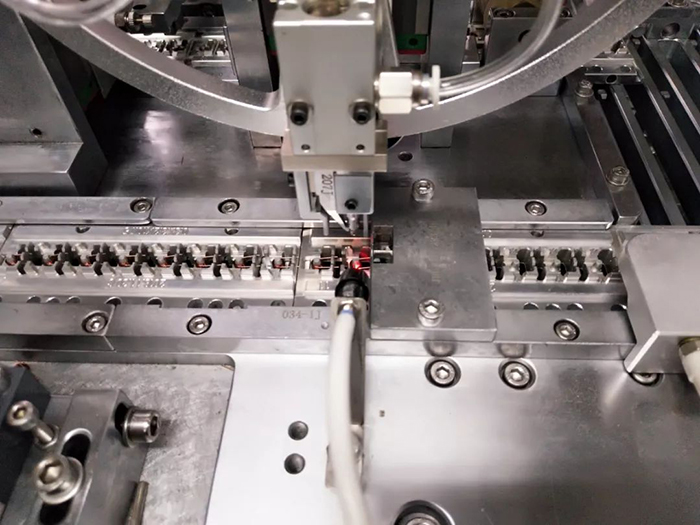

High frequency transformer automation production lines

Enterprises invest in automated production, in addition to reducing costs, there is an important factor to improve product quality. The product consistency of automated production is better, and the production capacity is stable. For example, the production

of high-frequency transformers, the use of automated production, its winding flat, rightEMIThe impact is small, reducing the human impact on the product, and greatly improving the quality of the product.

Automated production will effectively reduce production costs, reduce defective products, ensure quality, improve work efficiency, and maximize the benefit of customers.2019 ,Jinlai Technology will

also increase the progress of automated production, welcome new and old customers to inquire!