With the development of inductance devices towards low voltage, resistance to large DC bias, good temperature stability, miniaturization, thinness and lightweight, ordinary soft magnetic ferrite materials have been unable to meet such high requirements, and integrated inductance has stepped on the stage of history and become an important member of the inductance device family.

With the development of inductance devices towards low voltage, resistance to large DC bias, good temperature stability, miniaturization, thinness and lightweight, ordinary soft magnetic ferrite materials have been unable to meet such high requirements.Integrated inductorIt has boarded the stage of history and become an important member of the inductive device family.

Jinlai technology integrated forming inductor

In order to serve the market and hope to gain something in the integrated molding inductors, JINLAI Technology began to enter the field a few years ago, after several years of efforts, the integrated molding inductors made of alloy powder have now entered the mass production stage.

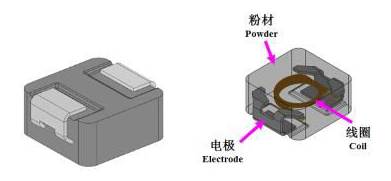

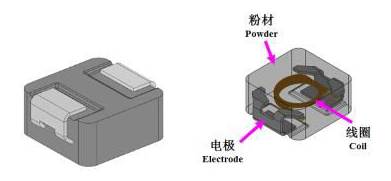

Jinlai Technology alloy powder integrated forming inductor

An integrated inductor consists of metal powder, electrodes and coils, as shown in the figure above.

Integrated inductors are suitable for DC-to-DC rectification of power lines in power supplies, personal computers and other handheld electronic devices. Contact if you need helpJinlai TechnologyCustomer service!